Overview

Venturi injectors are differential pressure injectors designed for precise fluid injection. The patented design and precise construction optimize injector efficiency, suction capacity, and mixing capabilities. With no moving parts, these injectors offer simplified maintenance, resulting in significantly lower operating costs compared to less efficient systems.

Key Highlights

• Advanced Design: Innovative shaping of the convergent, throat, and divergent sections ensures optimized injection rates.

• Enhanced Suction: Equipped with specially designed spiral vanes, a better flow profile is achieved delivering higher suction rates.

• Durability: Made from engineering-grade plastics and stainless steel for excellent chemical resistance.

• Adjustable Suction Rate: The suction rate of the injection fluid can be easily adjusted to meet specific application needs.

• Ozonation Efficiency: Ideal for ozonation applications with high ozone mass transfer rates, enhancing water treatment effectiveness.

• Flexible Options: Available in multiple sizes for versatile use across different systems.

• Reverse Flow Prevention: Integrated with an additional valve on the suction side to prevent reverse water flow.

Benefits

Cost-Efficiency: Economical solution with minimal maintenance costs due to the absence of moving parts.

• Optimized Performance: Patented design and internal mixing spirals enhance injection efficiency and uniform mixing.

• Compact and Lightweight: Fits into tight spaces and integrates easily into existing systems.

• Efficient Mixing and Distribution: Provides uniform mixing of injected fluids, enhancing overall system performance.

• Environmentally Friendly: Reduces the need for additional energy inputs like booster pumps when sufficient pressure differentials are available.

Applications

The Assi River, which discharges into the sacred Ganga River, has seen a drastic decline in water quality due to increasing levels of untreated sewage, exacerbated by rapid population growth in the surrounding area. The existing Sewage Treatment Plant (STP) was insufficient to meet the growing demand, resulting in untreated wastewater being discharged into the Ganga River through this channel. An alternative solution was urgently required to improve water quality and reduce contamination levels in the river.

• Agricultural Irrigation: Ideal for injecting fertilizers and chemicals in drip and sprinkler systems, enhancing crop yields.

• Water Treatment: Effective in delivering treatment chemicals and ozone in purification systems with high mass transfer rates.

• Chemical Processing: Suitable for precise dosing of various chemicals in industrial fluid management.

With its reliable performance, easy integration, and adjustable capabilities, the Vayuj Venturi Injector is a versatile and economical choice for fluid injection needs across diverse applications.

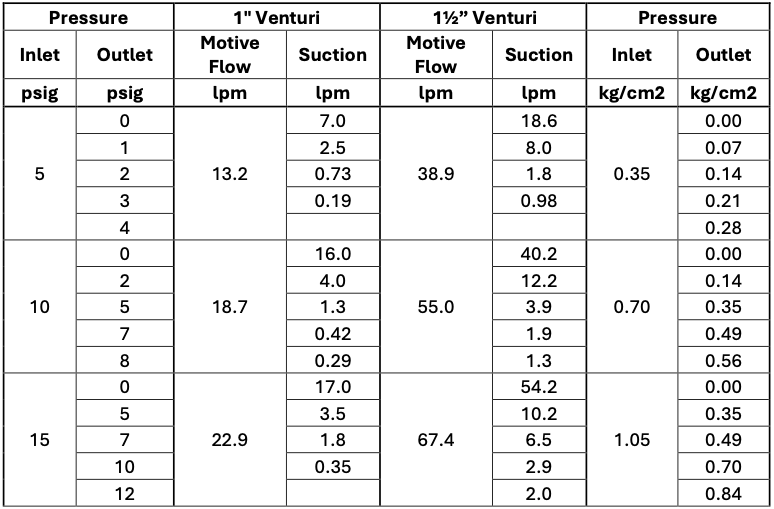

Performance Charts for Venturi Injectors